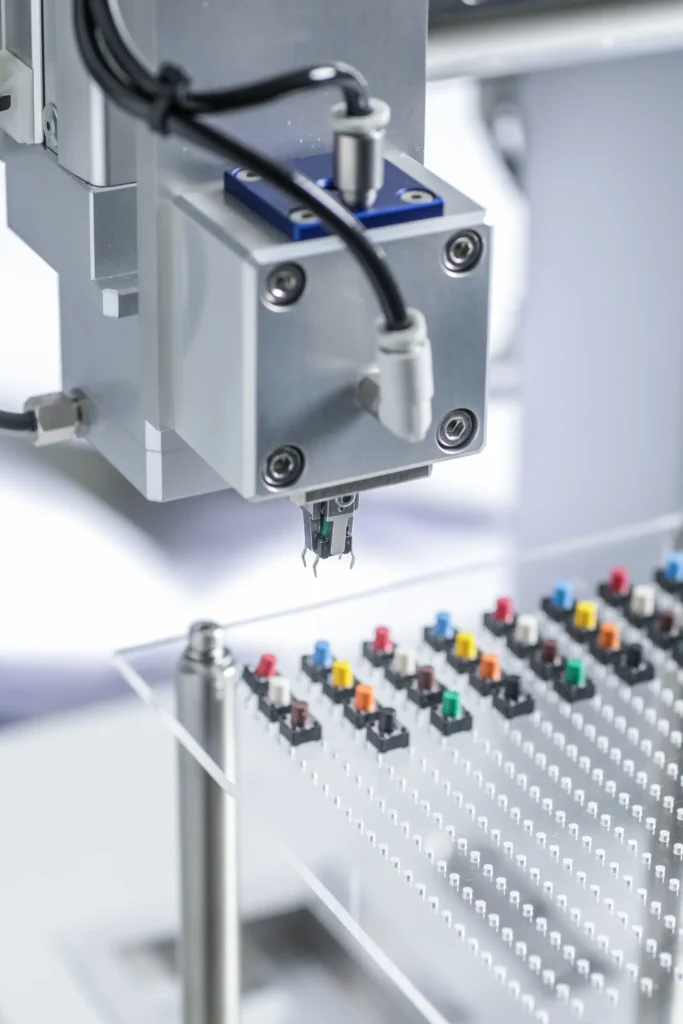

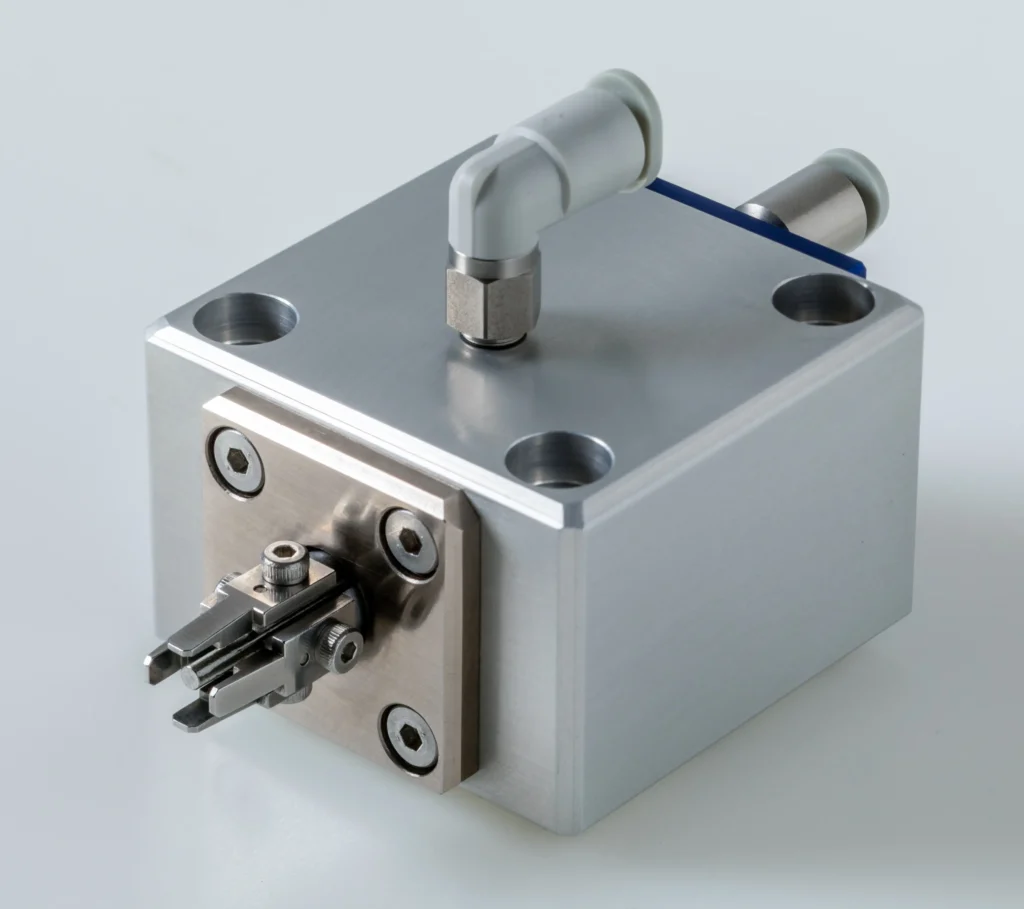

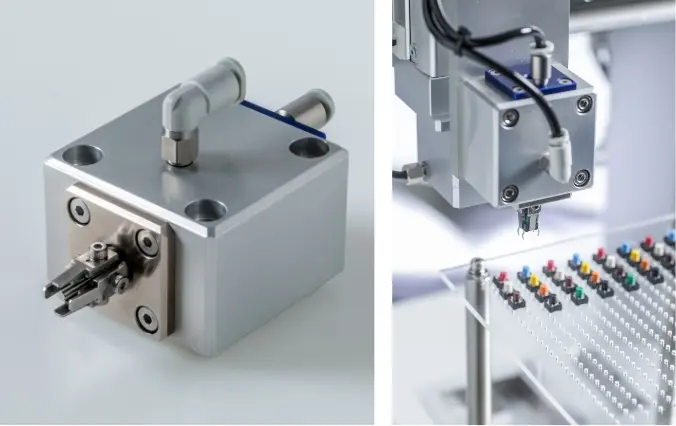

Collet Chucks, Hands and Units

Technology

Examples of High-Precision Machining Orders* In the field of machinery equipment, we specialize in R-shaped machining, thin-walled processing, and the production of special screws. Our services cover not only equipment components but also jigs and gauges. We cater to the automotive and aerospace industries, having produced valve components, F1 parts, motorcycle brake components, throttle shafts, and custom jigs and inspection tools.

Our finishing techniques, especially in taper sections and seat surfaces, are highly praised for their precision. By offering tailored technical solutions, we ensure every product meets our clients’ unique machining demands. Precision is key in all our processes, ensuring that your needs are met with the highest quality.

Challenging Materials Machining Expertise

We excel in machining complex and high-strength materials to meet our customers’ exacting standards. This includes working with materials resistant to temperature fluctuations and complex shapes. For instance, we specialize in machining heat-resistant materials like SUH660, ensuring both high precision and durability. From single prototypes to full production runs, we accommodate all custom orders with flexibility and care, making us your go-to partner for challenging machining requirements.

Precision Guide Bushes for Superior Machining

Our high-quality guide bushes are designed to provide exceptional precision and stability in machining operations. Engineered to minimize wear and improve overall performance, these guide bushes are ideal for maintaining accurate alignment and reducing tool deflection. Whether you’re working with automotive parts, medical devices, or complex shaft components, our guide bushes deliver reliable results in even the most demanding applications. Upgrade your machinery with our durable and high-performance guide bushes for improved efficiency and precision in every operation. Precision, workholding, machinery, performance, durability, and machining.

We excel in machining complex and high-strength materials to meet our customers’ exacting standards. This includes working with materials resistant to temperature fluctuations and complex shapes. For instance, we specialize in machining heat-resistant materials like SUH660, ensuring both high precision and durability. From single prototypes to full production runs, we accommodate all custom orders with flexibility and care, making us your go-to partner for challenging machining requirements.

Help us understand your needs by answering the questions below.

To ensure we deliver the perfect solution for your machining needs, we ask for the following details:

- A drawing of the metallic object, indicating which part of the object needs to be grasped.

- The type of material being used.

- How the object is to be grasped.

- The intended operation or function (what will be done with the object).

- The required precision for the operation.

- The desired runout accuracy for the final product.

With this information, we can tailor our collet chucks, collet hands, chuck units, and spindles to meet your specific machining requirements and ensure optimal performance.

Product Line

To ensure we deliver the perfect solution for your machining needs, we ask for the following details:

Collet Chucks

Our highperformance collet chucks deliver precision and stability in a variety of machining operations.

Collet Hands

With a focus on durability and accuracy, our collet hands ensure excellent grip and operational efficiency, making them ideal for various material types.

Chuck Units

Our advanced chuck units provide secure and precise workholding, enhancing both productivity and accuracy in machining

tasks. These units can also be used for crimping operations, offering versatility in production lines.

Spindles

Designed for speed and reliability, our spindles deliver top-tier performance and long-lasting durability, especially suited for industries like automotive and medical device manufacturing.

Gallery