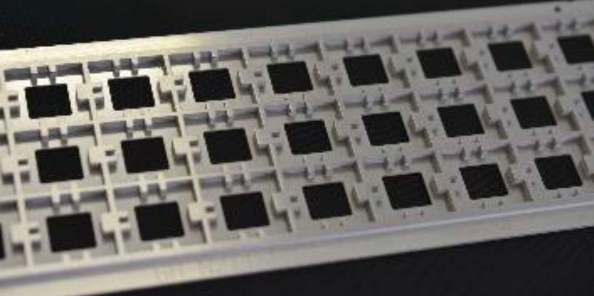

Manufacturing processing and transport jigs for semiconductor production lines and equipment.

Experience the innovative jigs

Revolutionize Your Operations with Advanced Jigs

Now is the perfect moment to discover the exceptional power of our jigs. With our state-of-the-art diffusion bonding technology, you’ll experience performance and reliability like never before.

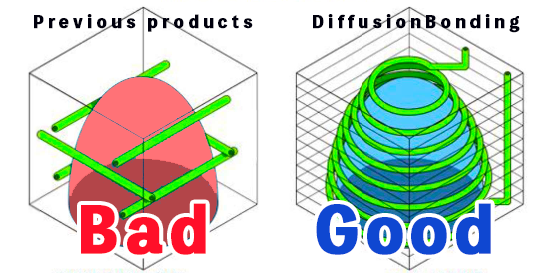

The Power of Diffusion Bonding

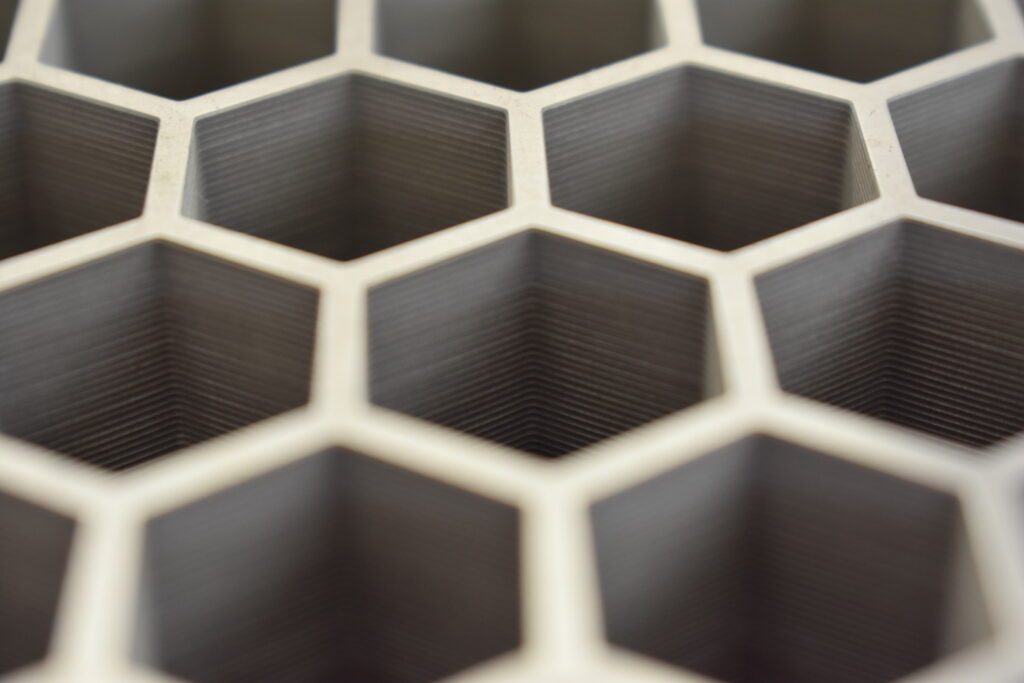

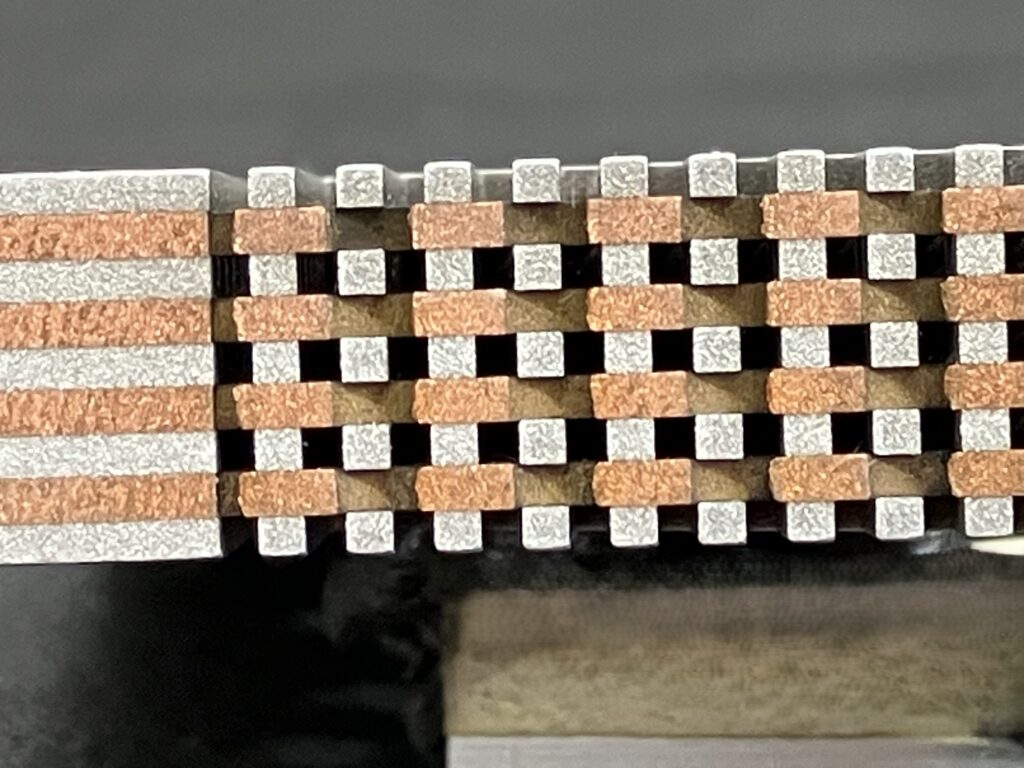

Moving beyond traditional techniques like welding or soldering, diffusion bonding fuses metals by applying controlled heat and pressure, allowing atoms to merge at the molecular level. This process creates a seamless, robust bond that is as strong as the original materials.

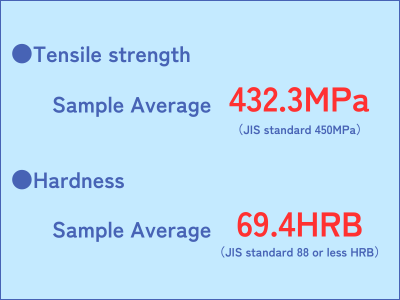

Unmatched Strength and Durability

Our diffusion bonding delivers exceptional bond strength, making it ideal for applications that demand the highest levels of durability and reliability. The bond created is not just strong but also long-lasting, ensuring consistent performance over time.

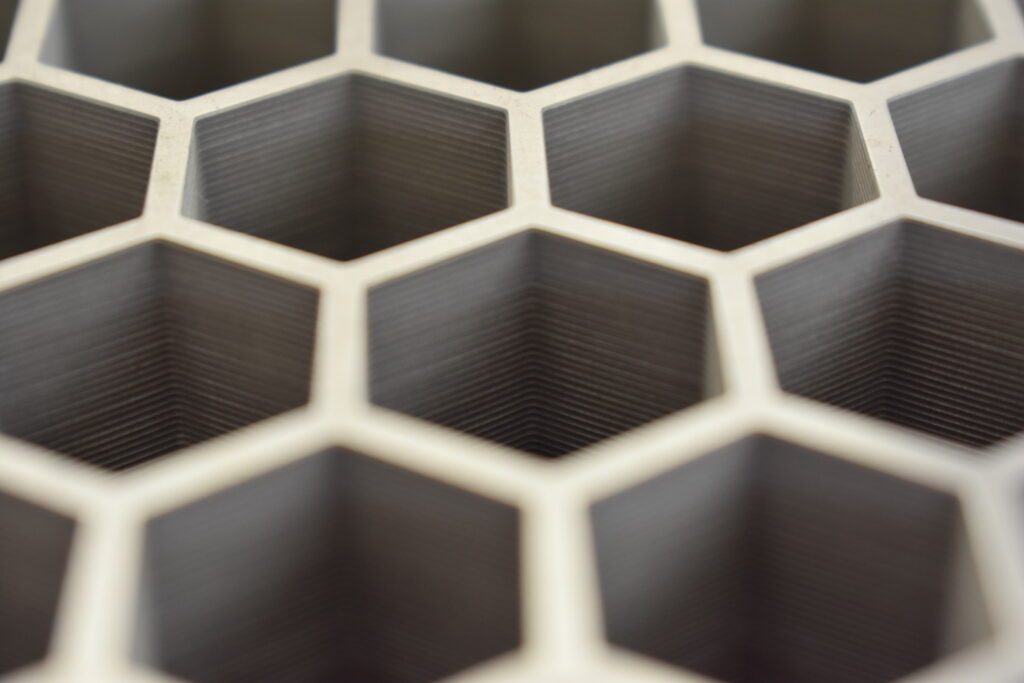

Enhanced Efficiency in Power and Heat Transfer

With a large bonding area, diffusion bonding significantly improves the efficiency of power transmission and heat conduction. This process maximizes the contact between materials, leading to faster response rates and better thermal management.

Precision Engineering with No Compromises

Our meticulous control over the diffusion bonding process ensures high-precision joins with minimal distortion. By eliminating the need for additional materials, we also reduce the risk of corrosion, preserving the integrity of the bond in demanding environments.

.jpg)

Performance in Extreme Conditions

Designed to withstand high temperatures, our diffusion bonding technology ensures that joints remain stable and resist degradation, even in the most challenging conditions. This makes it the perfect solution for applications requiring consistent performance under stress.

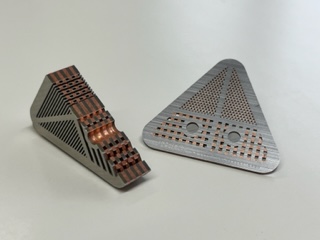

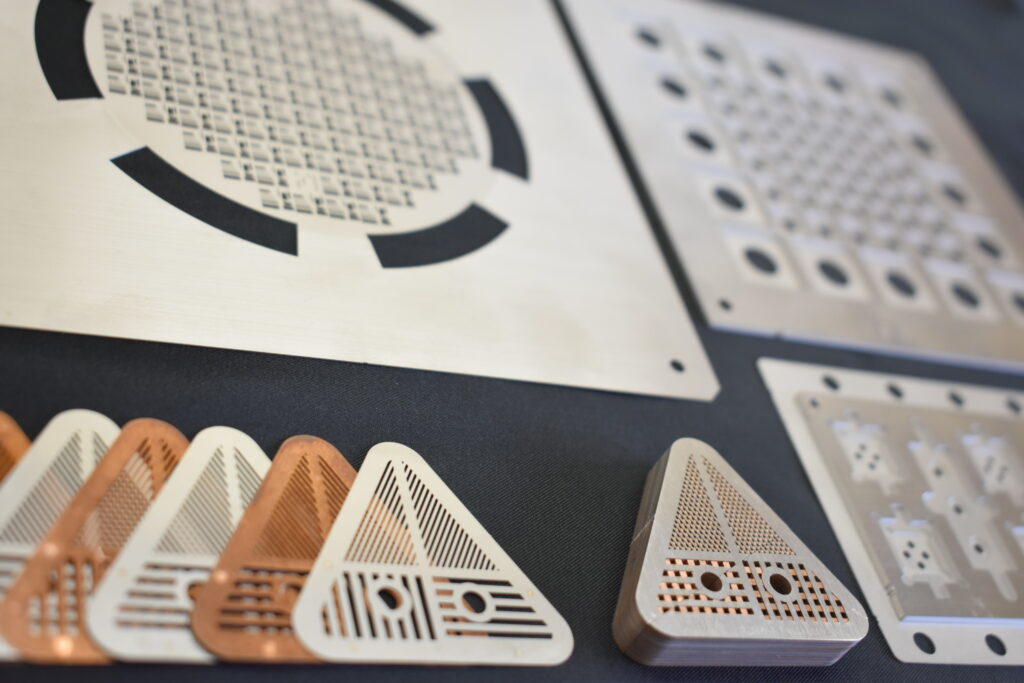

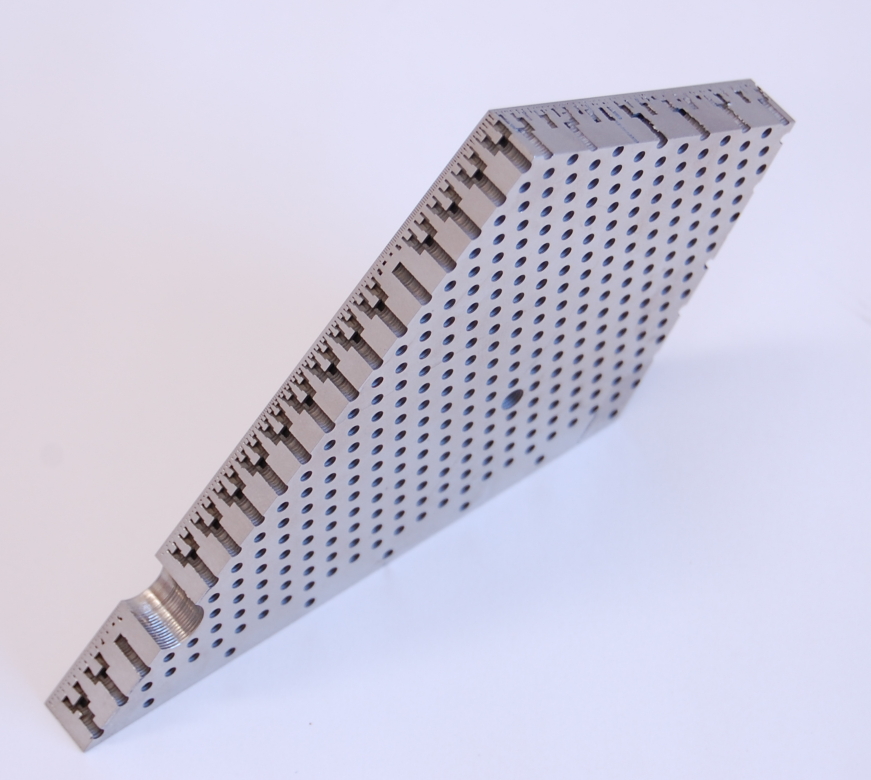

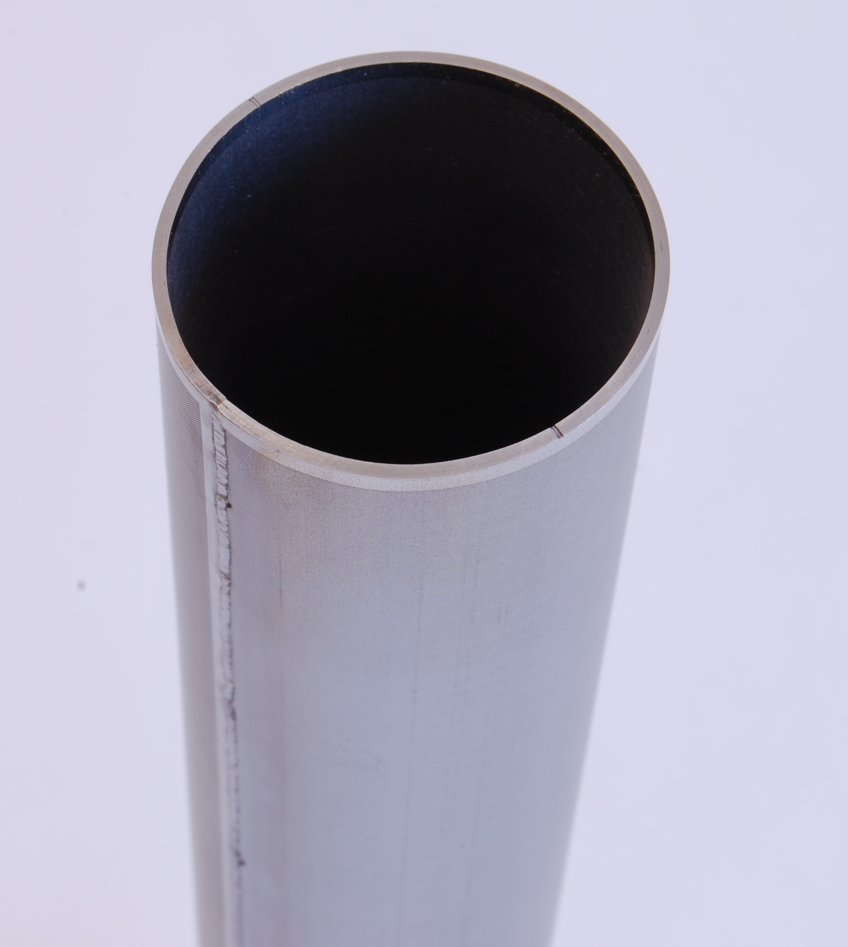

Application example

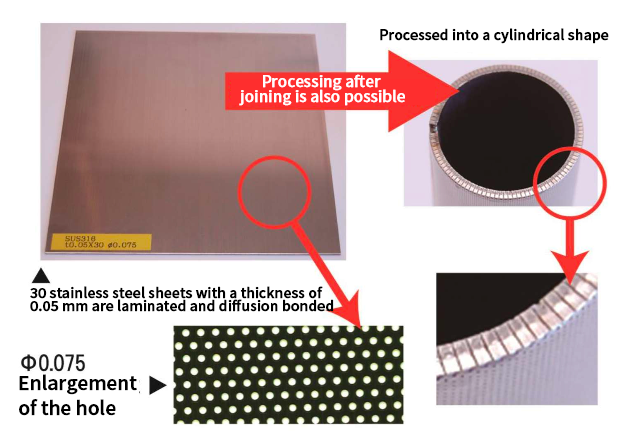

Stainless steel filter with a thickness of 1.5 mm and a diameter of 0.075 mm

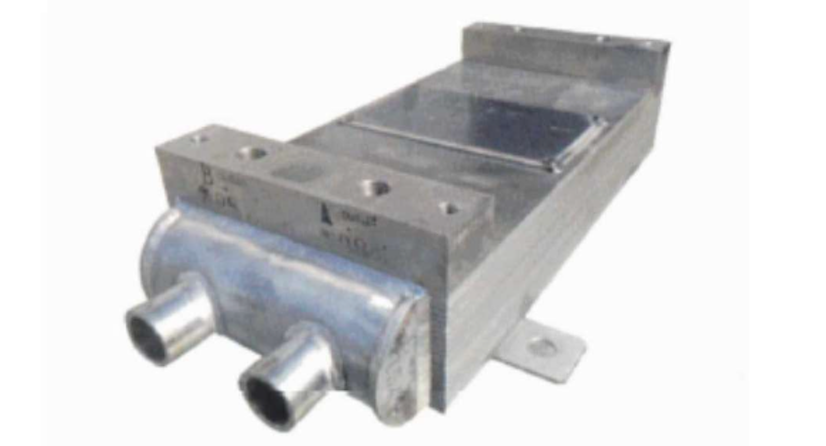

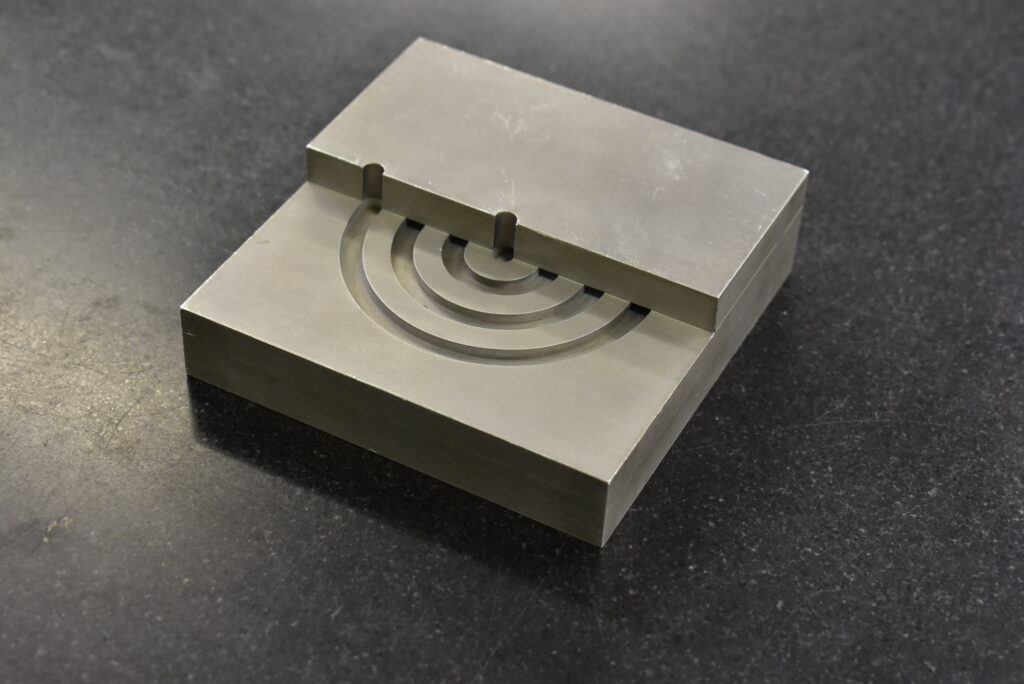

Heat exchanger for hydrogen stations compatible with 200MPa

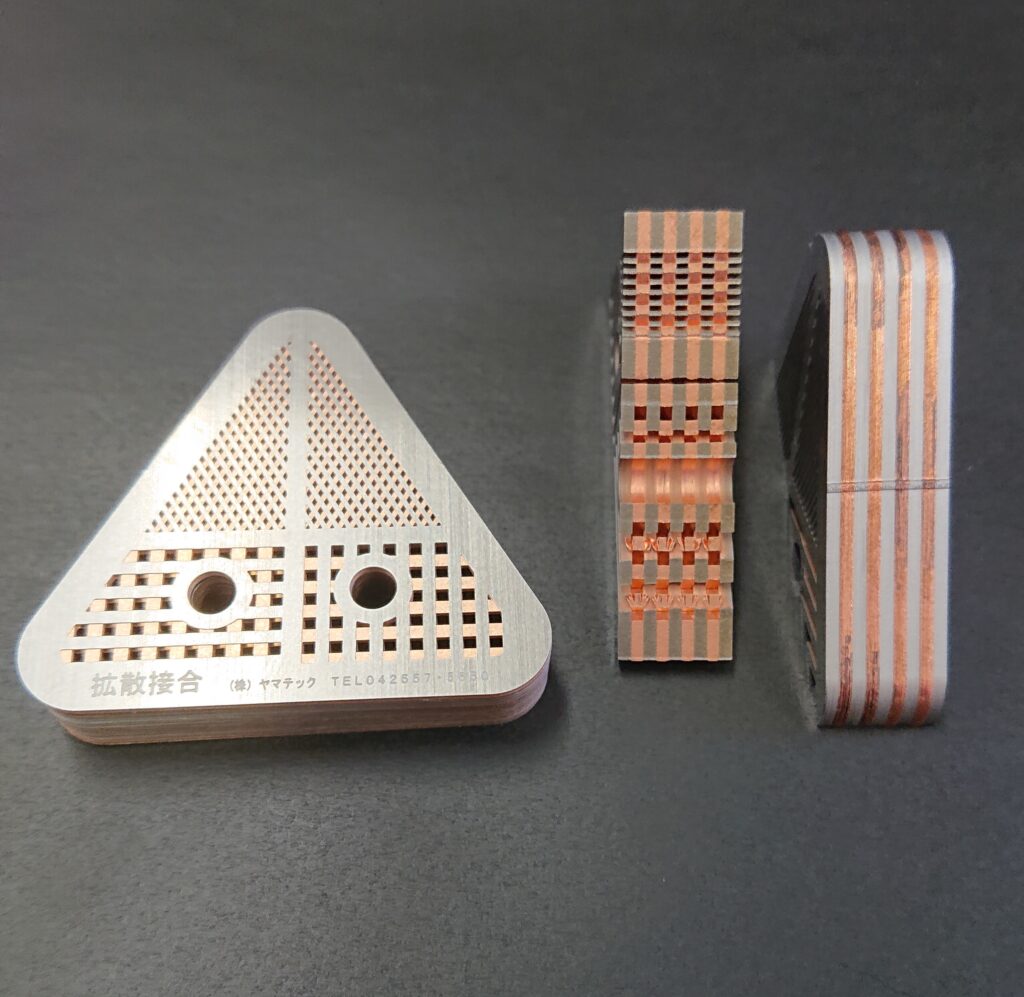

Tools like transport trays feature seamless edges with no radius, a precision that cutting alone cannot achieve.

PRODUCT IMAGE

VIDEO

Contact Us

Don’t hesitate to get in touch—whether you have questions, need support, or are interested in exploring collaboration opportunities. We’re here to listen and respond quickly, ensuring a seamless experience every step of the way.

【Materials utilized in bonding】

| Stainless Steel | SUS303 SUS304 SUS310S SUS316 SUS316L SUS430 SUS420J2 SUS440 etc |

| Nickel-based | 42Alloy Invar Kovar Monell |

| Copper | Oxygen-free copper Tough Pitch Copper |

| Aluminum | 2017 5052 6061 6063 7075 |

| Titanium | Pure Titanium |

| Mold Material | HPM38 HPM77 SKD61 STAVAX S55C etc |